At a manufacturing facility specializing in the production of steel strips, a critical quality control challenge arose with regard to appearance defects in 12mm steel strips. To address this problem, the facility implemented a state-of-the-art machine vision inspection system tailored to detect and categorize various appearance defects in steel strips, ensuring that only high-quality products reach the market.

The machine vision system was strategically integrated into the production line after the steel strips were cut to the desired width of 12mm. As each steel strip moves along the conveyor belt, a high-resolution industrial camera captures detailed images of its surface, focusing on detecting defects such as scratches, dents, discoloration, or any other irregularities that could compromise the strip’s appearance quality.

Inspection information:

The goal of this project is to use Intsoft Tech artificial intelligence vision system to detect upper and lower surface defects in the steel strip. The main points are as follows:

1. Product width: about 12mm, running speed 10 meters/minute. The inspection is a random inspection, and the initial design is to shoot and analyze once per second.

2. The inspection range includes the upper and lower sides of the product.

3. Defect types include: pits, abnormal variegated colors. There are also black textures on the surface of qualified products that need to be filtered out to avoid false alarms.

Project name: Steel strip surface defect detection

Project category: Defect detection-pits, variegated colors

Field of view: 20mm*15mm

Detection accuracy: 0.01mm (visible to the human eye)

Movement speed: 100 meters/minute

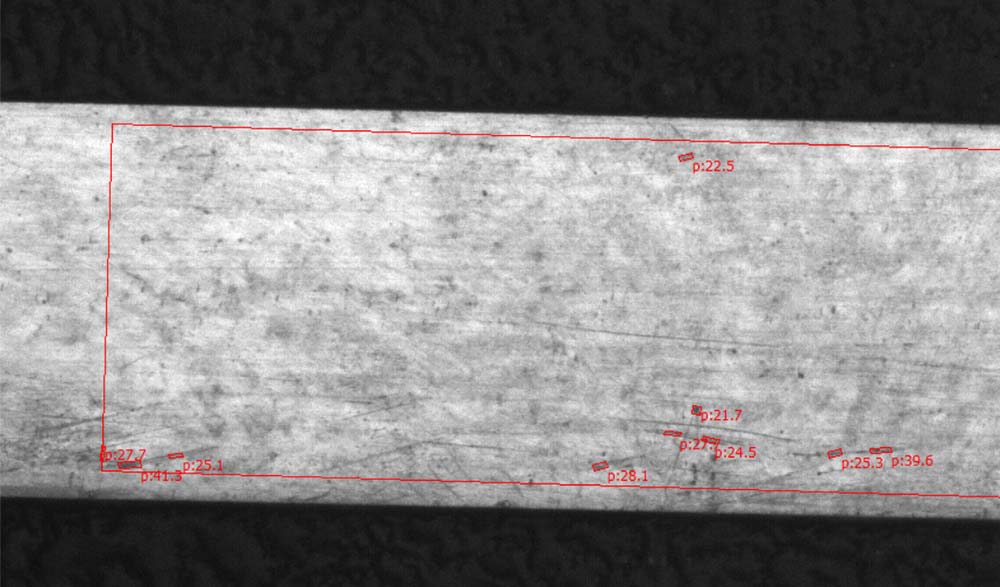

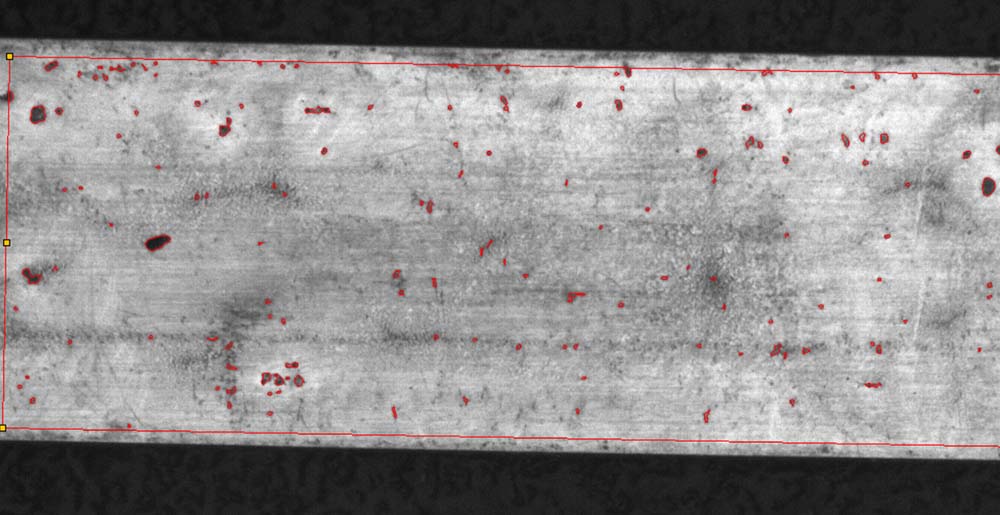

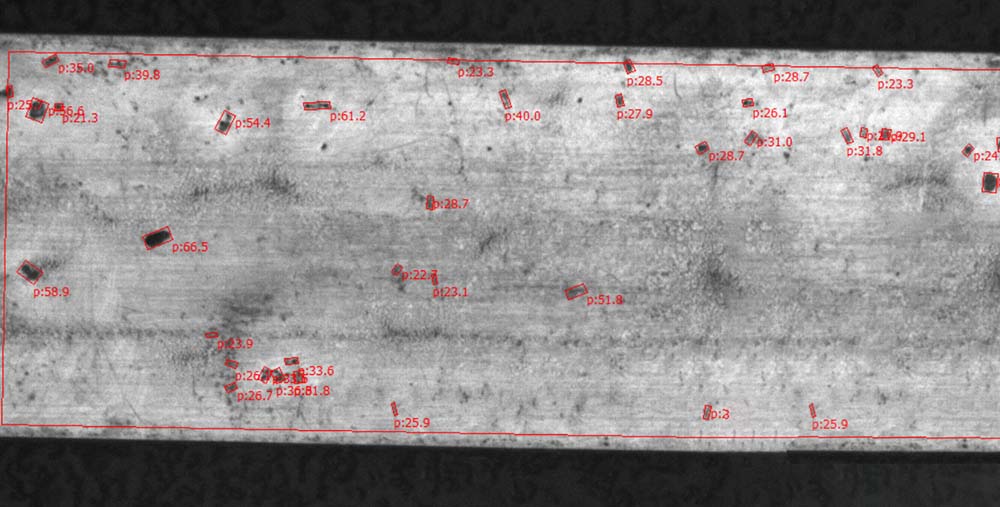

Inspection results

All defect areas analyzed by the software (marked in red)

Display data by circumference and ignore areas with a circumference of less than 20

Low-precision detection, even small scratches are still “qualified”.