Machine Vision vs. Machine Learning: Understanding the Differences and Intersections

Introduction

In recent years, the fields of machine vision and machine learning have gained significant attention across various industries, from manufacturing to healthcare. Both technologies play crucial roles in automating processes and enhancing decision-making capabilities. However, they serve different purposes and operate on distinct principles. This article explores the differences and intersections between machine vision and machine learning, offering insights into how they complement each other in practical applications.

Understanding Machine Vision

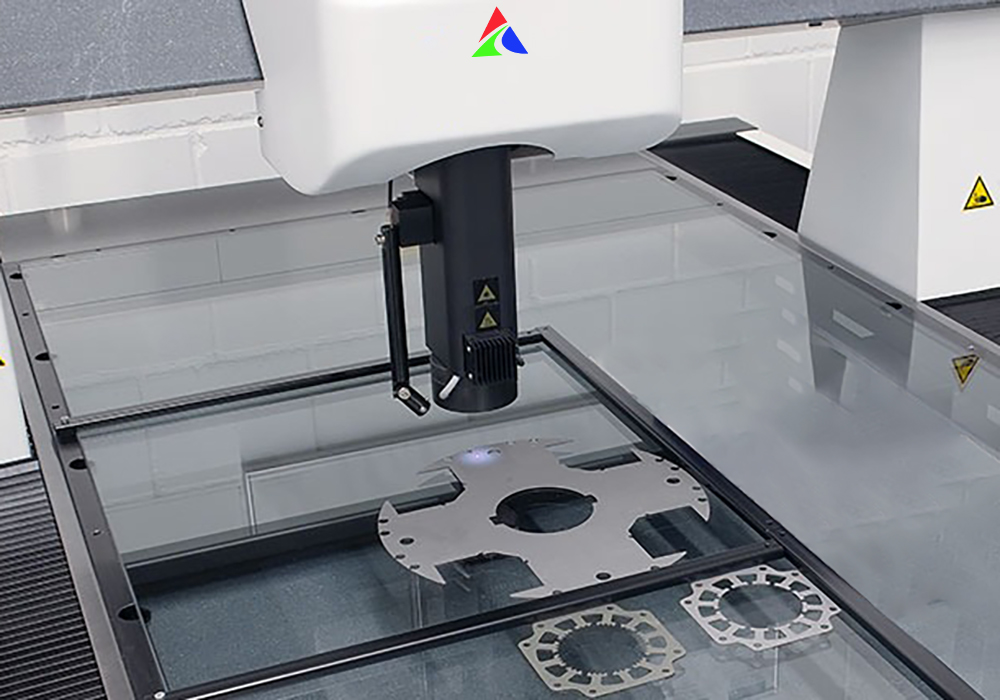

What is Machine Vision?

Machine vision refers to the capability of a computer system to interpret and understand visual information from the world around it. It involves the use of cameras and image processing software to capture, analyze, and make decisions based on visual data. Machine vision systems are widely used for tasks such as inspection, measurement, and identification in various industries, particularly manufacturing.

Key Components of Machine Vision

- Cameras: High-resolution cameras capture images of the objects or scenes being analyzed. Different types of cameras (e.g., CCD, CMOS) are used based on the application requirements.

- Lighting: Proper lighting is crucial for obtaining clear images. Various lighting techniques (e.g., backlighting, diffuse lighting) are employed to enhance visibility and reduce shadows.

- Image Processing Software: This software analyzes the captured images to extract relevant features, detect defects, and perform measurements. Algorithms may include edge detection, pattern recognition, and color analysis.

- Interface and Output: The processed data is typically presented through a user interface, enabling operators to make informed decisions based on the analysis.

Applications of Machine Vision

Machine vision has a wide range of applications, including:

- Quality Control: Inspecting products for defects or inconsistencies during manufacturing processes.

- Automated Sorting: Classifying and sorting items based on size, shape, or color.

- Robotics Guidance: Assisting robots in identifying and interacting with objects.

- Barcode and QR Code Reading: Scanning codes to retrieve information or track inventory.

Understanding Machine Learning

What is Machine Learning?

Machine learning is a subset of artificial intelligence (AI) that enables systems to learn from data and improve their performance over time without being explicitly programmed. It involves the development of algorithms that can identify patterns, make predictions, and adapt to new information. Machine learning is widely used in various domains, including finance, healthcare, marketing, and more.

Key Components of Machine Learning

- Data: High-quality data is essential for training machine learning models. The data can be structured (e.g., databases) or unstructured (e.g., images, text).

- Algorithms: Machine learning algorithms are used to analyze data and extract patterns. Common types of algorithms include supervised learning, unsupervised learning, and reinforcement learning.

- Model Training: During the training phase, the algorithm learns from the data by adjusting its parameters to minimize errors in predictions.

- Evaluation: After training, the model is evaluated using a separate dataset to assess its performance and generalization capabilities.

Applications of Machine Learning

Machine learning is employed in various applications, such as:

- Predictive Analytics: Forecasting future trends based on historical data.

- Natural Language Processing (NLP): Enabling machines to understand and respond to human language.

- Recommendation Systems: Suggesting products or content based on user behavior and preferences.

- Fraud Detection: Identifying suspicious activities in financial transactions.

Key Differences Between Machine Vision and Machine Learning

1. Purpose

- Machine Vision: Primarily focuses on interpreting visual data to perform tasks such as inspection, measurement, and identification.

- Machine Learning: Aims to enable systems to learn from data and make predictions or decisions based on that data.

2. Data Type

- Machine Vision: Works primarily with visual data (images and videos) captured by cameras.

- Machine Learning: Can work with various types of data, including text, numerical data, images, and more.

3. Techniques Used

- Machine Vision: Utilizes image processing techniques and algorithms specifically designed for analyzing visual data.

- Machine Learning: Employs statistical methods and algorithms to analyze data and identify patterns, regardless of the data type.

4. Output

- Machine Vision: Provides outputs related to visual analysis, such as defect detection, measurements, or object classification.

- Machine Learning: Produces predictions, classifications, or recommendations based on the learned patterns from the data.

5. Complexity

- Machine Vision: Often involves specific technical challenges related to image capture, lighting, and environmental conditions.

- Machine Learning: Focuses on the complexity of data analysis, model training, and generalization to new data.

Intersections Between Machine Vision and Machine Learning

While machine vision and machine learning are distinct fields, they often intersect and complement each other in practical applications. Here are some ways they work together:

1. Enhanced Image Analysis

Machine learning algorithms can be applied to improve the analysis of visual data in machine vision systems. For instance, deep learning techniques, particularly convolutional neural networks (CNNs), have revolutionized image classification and object detection, enabling systems to recognize complex patterns in images.

2. Improved Quality Control

In manufacturing, machine vision systems equipped with machine learning capabilities can continuously learn from inspection data. This allows the system to adapt to new defects or variations in products, enhancing the quality control process over time.

3. Real-Time Decision Making

By integrating machine learning with machine vision, systems can make real-time decisions based on visual inputs. For example, in automated sorting applications, machine learning models can classify objects on the fly, improving efficiency and accuracy.

4. Predictive Maintenance

Combining machine vision with machine learning can facilitate predictive maintenance in industrial settings. Machine vision can be used to monitor equipment condition visually, while machine learning algorithms analyze historical data to predict potential failures, allowing for timely interventions.

5. Autonomous Robotics

In robotics, machine vision provides the visual input necessary for navigation and interaction with the environment. Machine learning enhances these systems by allowing robots to learn from their experiences, improving their ability to adapt to changing surroundings.

Challenges and Considerations

1. Data Quality

Both machine vision and machine learning rely heavily on data quality. Poor-quality images or insufficient training data can lead to inaccurate results and decisions.

2. Complexity of Implementation

Integrating machine vision and machine learning can be complex and may require specialized expertise. Organizations need to invest in skilled personnel and appropriate tools to ensure successful implementation.

3. Computational Requirements

Machine learning, especially deep learning, can be computationally intensive. Organizations must consider the necessary hardware and infrastructure to support these technologies.

4. Real-World Variability

In real-world applications, environmental conditions, lighting variations, and object appearances can change. Systems must be robust enough to handle these variations to maintain accuracy.

Future Trends

1. Increased Automation

As industries continue to embrace automation, the integration of machine vision and machine learning will become more prevalent. This trend will lead to smarter manufacturing processes and improved operational efficiency.

2. Advancements in AI

Ongoing advancements in AI will further enhance the capabilities of machine vision and machine learning. New algorithms and techniques will enable more sophisticated analysis and decision-making.

3. Edge Computing

The rise of edge computing will allow for real-time processing of visual data closer to the source, reducing latency and improving response times in applications such as autonomous vehicles and industrial automation.

4. Enhanced User Interfaces

Improved user interfaces and visualization tools will make it easier for operators to interact with machine vision and machine learning systems, enabling better decision-making and oversight.

Machine Vision vs. Machine Learning

Machine vision and machine learning are two distinct yet interconnected fields that play crucial roles in modern automation and data analysis. While machine vision focuses on interpreting visual data, machine learning empowers systems to learn and adapt based on that data. Their integration offers significant advantages across various industries, enhancing quality control, efficiency, and decision-making capabilities. As technology continues to evolve, the synergy between machine vision and machine learning will likely lead to even greater innovations and applications, shaping the future of automation and intelligent systems.