The photovoltaic industry is still in a state of development. Many of us have rows of solar panels installed on our roofs to convert solar energy into electricity for daily lighting, cooking, refrigeration, production, etc.

The following is few case study of solar panel defect detection by Intsoft Technology.

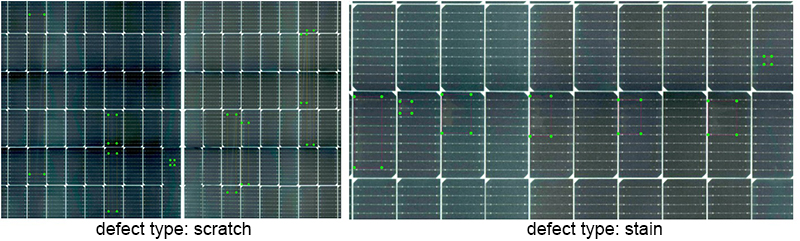

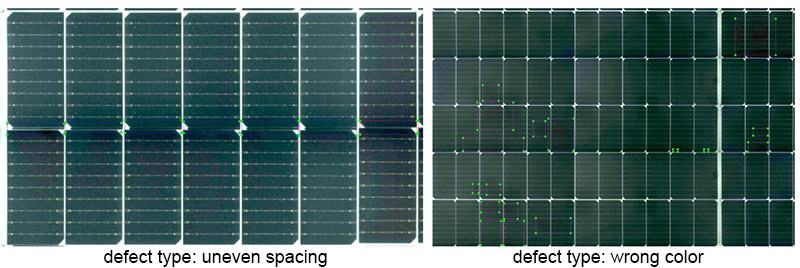

Solar Panel Defect Detection Solution 1: Direct Identification Scratches, dirt, uneven spacing, abnormal color, misalignment, broken edges, missing corners, etc.

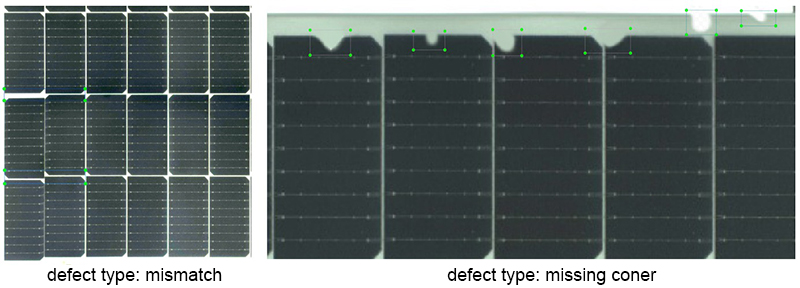

Solar panel defect detection solution 2: Scanning and identification by scanner

Black pieces, black spots pieces, short-circuited black pieces, overwelded pieces, broken grid pieces, bright and dark pieces, hidden cracks and other defects

Detailed defect types for identification

Detection result:

Basic Solution for AI Visual Inspection of Solar Panels

Consistent Image Acquisition:

- Ensuring that camera positioning, angle, and lighting conditions are stable and uniform throughout all inspections is critical for reliable defect detection.

- Any variation in the image acquisition setup can introduce errors and lead to inconsistent results.

High Quality Image Preprocessing:

- Proper preprocessing techniques, such as noise reduction, brightness adjustment, and image segmentation, are essential to enhance image quality and clarity.

- Poor preprocessing can result in the loss of important visual features needed for accurate defect identification.

Robust Defect Detection Algorithms:

- The performance of the deep learning-based defect detection models (e.g., convolutional neural networks) heavily depends on the quality and diversity of the training data.

- Insufficient or biased training data can lead to poor generalization and false positive/negative detection.

- Careful optimization of the model architecture and hyperparameters is required to achieve high accuracy and reliability.

Precise Defect Localization:

- Accurately locating the location and size of the detected defects on the surface of the solar panel is crucial for targeted maintenance and repairs.

- Inaccurate localization can lead to ineffective or ineffective remedial actions.

Integration with Production/Maintenance Systems:

- Seamless integration of the machine vision inspection system with solar panel manufacturing or maintenance workflows is essential for real-time monitoring and automated decision-making.

- Poor integration can lead to delays, silos of data, and suboptimal utilization of inspection insights.

Continuous monitoring and improvement:

- Regularly monitoring the performance of the machine vision inspection system and updating the models, algorithms, and workflows as needed is critical to maintaining high accuracy and relevance over time.

- Failure to adapt to changes in solar panel designs, manufacturing processes, or operating conditions can lead to a deterioration in the effectiveness of the inspection system.