When we use a laser machine to engrave text and patterns, or cut objects, we often need to position the object to be processed to a specific position without deviation, otherwise the path of engraving or cutting will be offset. This is very time-consuming. In batch production, each object must repeat this positioning step, which not only affects production efficiency, but also has the disadvantage of inaccurate positioning.

Is there a solution to this problem? Yes. This problem can be solved by using a machine vision device.

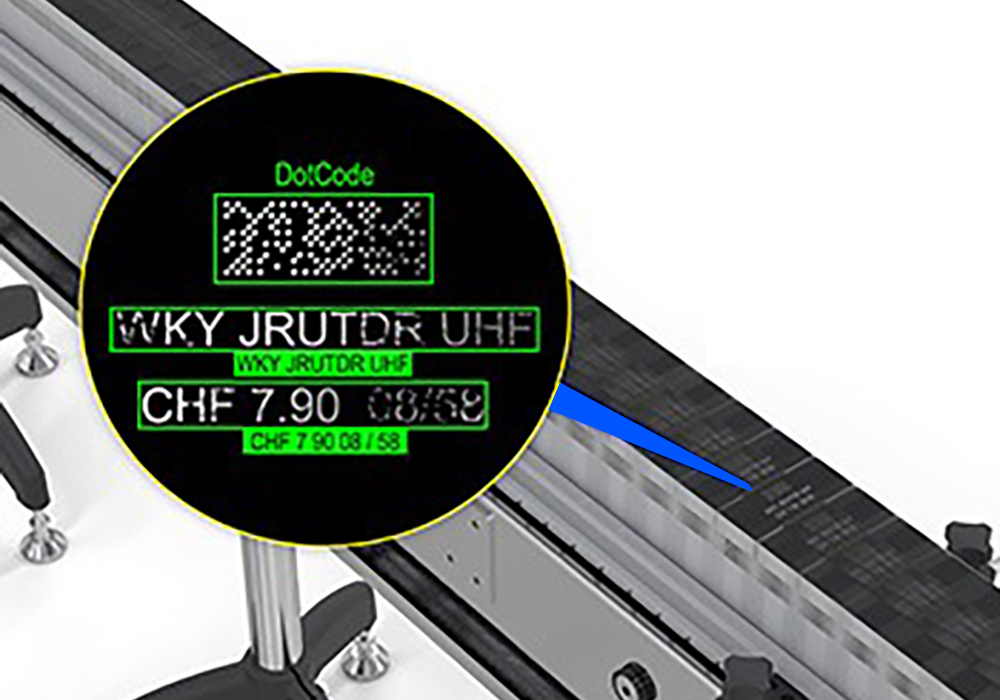

The machine vision device identifies the position of the object being processed, sends instructions to the laser machine, and adjusts the position of the laser head to adapt to the object being processed. As long as the object is placed in the designated area, no matter how it is placed, the laser can fall correctly on the designed position.

Advantages of laser marking machine vision positioning system for assembly lines

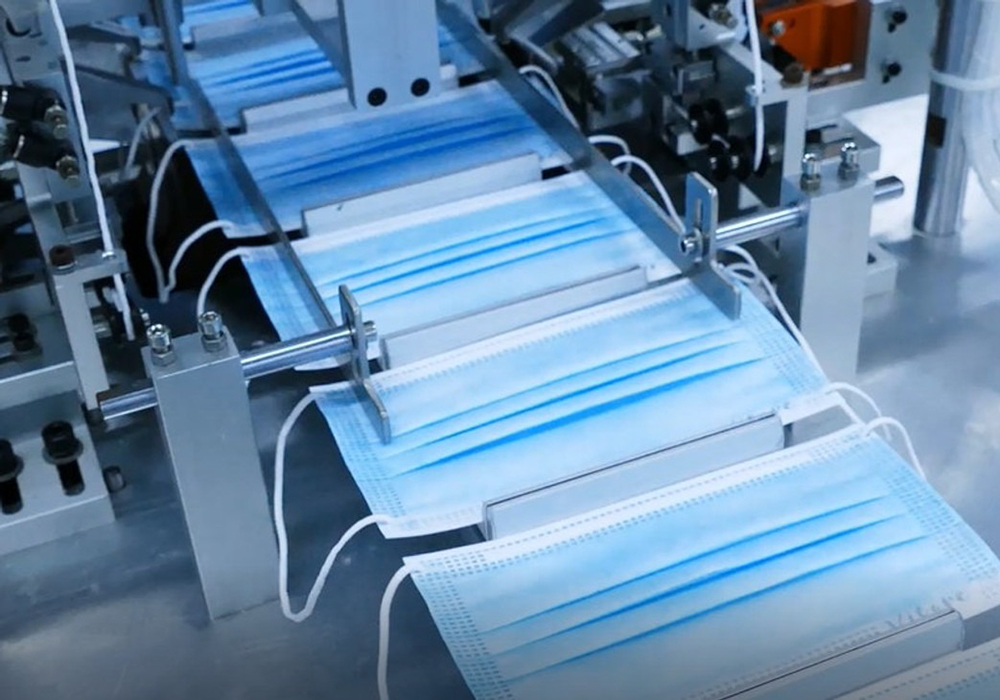

1. It is easy to insert into various assembly lines, supports conveyor belts and XY stages, and realizes fully automatic positioning and marking. It can also be connected to vibration plates and automatic feeders to achieve fully automatic laser marking.

2. It has a large visual range and supports mainstream lasers such as UV, optical fiber and CO2, which are suitable for most products.

3. The software automatically recognizes and automatically marks the product at any position, angle, and quantity.

4. The RVvision software algorithm has high positioning accuracy and fast response speed.

5. The fool-style operation interface has a one-button correction function, making the operation simpler and clearer, and ordinary employees can get started with a few minutes of study .

6. Machine vision equipment can be customized according to product size, product characteristics, assembly line states. If you need a laser marking visual positioning system in your manufacturing, please contact us. We can make your assembly line look brand new and save money.