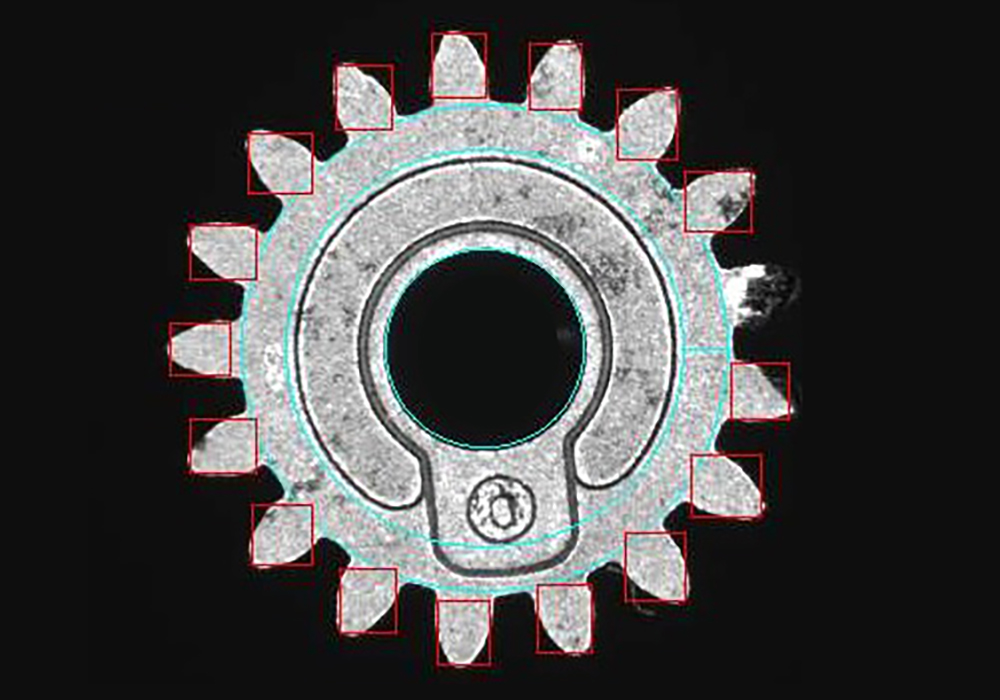

As a key transmission component in automobiles, the manufacturing accuracy of gear parts is crucial to the performance and service life of the entire vehicle. Among them, the height from the center circle of each pin to the outer diameter is a key indicator, which directly affects the noise, vibration and load-bearing capacity of the gear. Through machine vision inspection, more accurate inspection can be achieved and inspection efficiency can be improved. The following inspection cases are from Intsoft Tech.

Inspection Items and Purposes:

Measure the height of each pin from the inner circle to the outer circle, and screen out gears with substandard quality whose height is not within the error range, so as to facilitate the subsequent correction of gears.

Inspection system design:

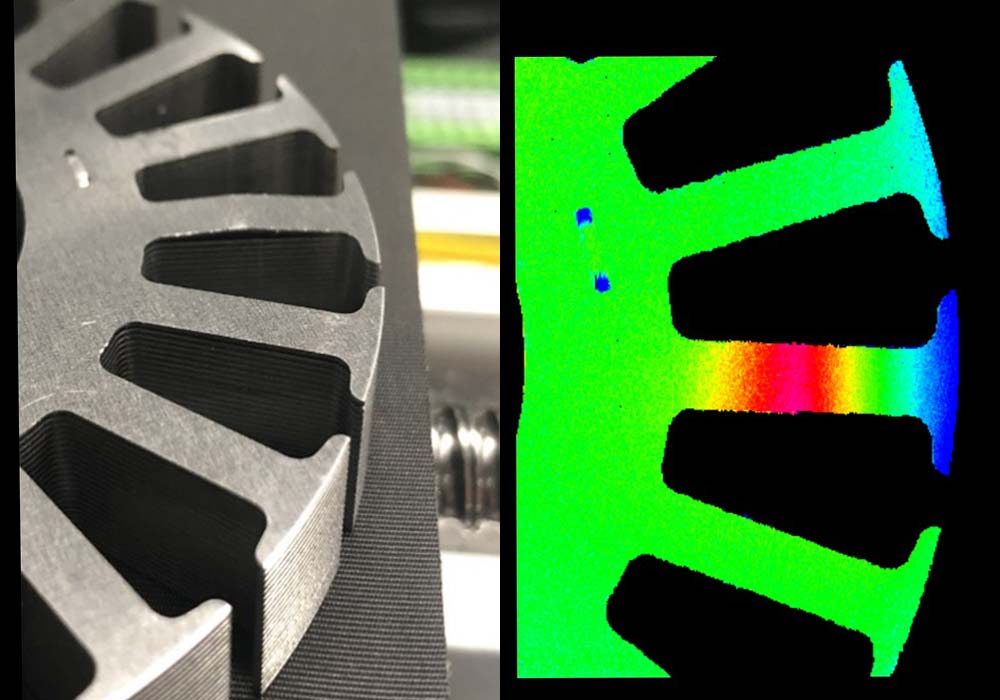

1. Use high-precision cognex industrial camera to scan gears and obtain high-precision 3D point cloud data in the range of 100mmx100mm

2. Develop a dedicated algorithm and use parallel computing architecture (AMD Ryzen Threadripper+ NVIDIA Quadro) to quickly extract height information from the top plane of each pin to the reference plane.

3. With Intsoft Tech’s customized feeding system, fully automated inspection is achieved.

4. Through Intsoft Tech control system and algorithm, inspection results are obtained and stored in the industrial computer.

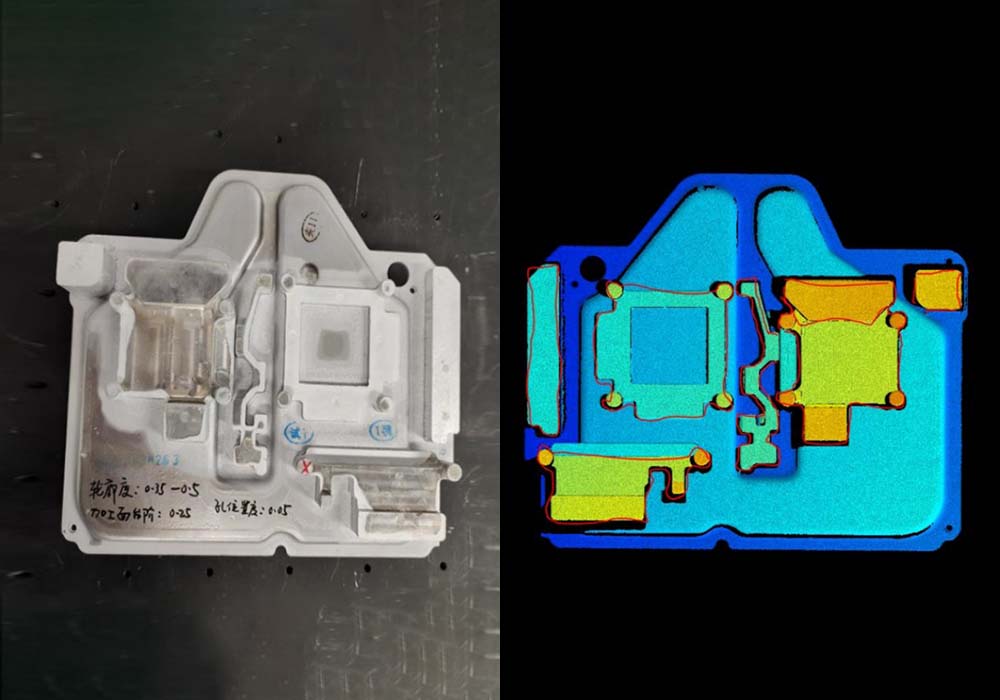

Inspection effect:

1. The single-piece test time is about 5 seconds, and about 600 pieces per hour can be automatically inspected.

2. The Z-axis measurement accuracy reaches 0.05-0.1mm, meeting the technical requirements.

3. Inspection results can be displayed and saved in real time, providing data support for subsequent gear quality control.

4. The transition from manual testing to fully automatic testing has been achieved, greatly improving inspection efficiency and data reliability.