Solution overview:

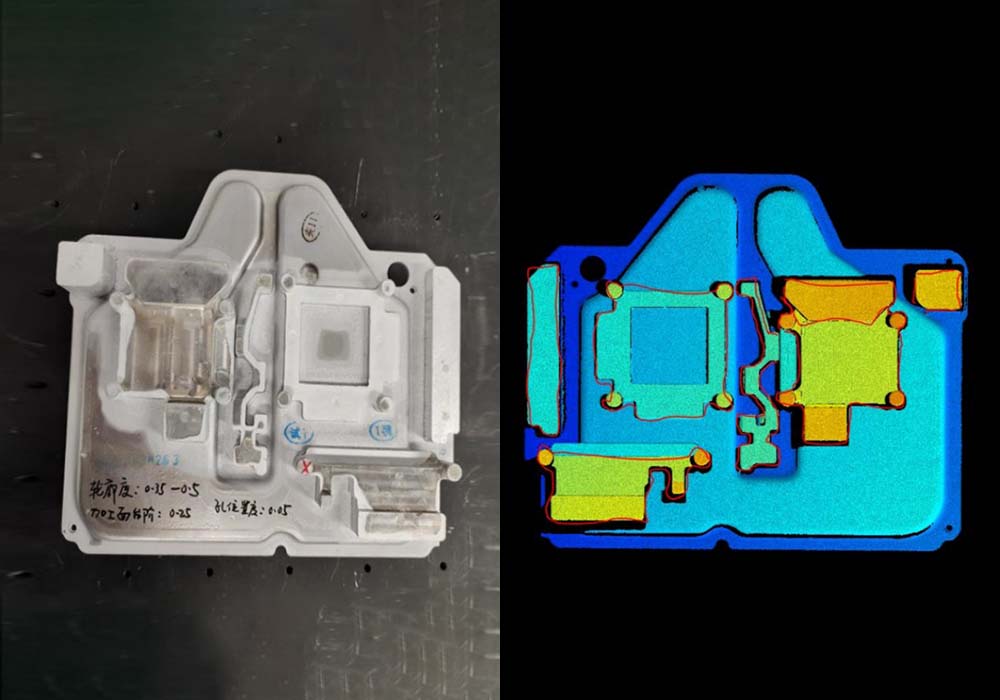

As one of the key components of thermal management of new energy vehicles, the line contour and position indicators of water cooling plate assemblies have a direct impact on the heat dissipation of the entire vehicle. To ensure product quality, new energy vehicle companies use machine vision equipment to detect water cooling plate assemblies.

The solution mainly includes the following steps:

Automatic loading: The water cooling plate assembly automatically enters the detection area through the conveyor line, and the industrial robot arm (FANUC M-20iA) accurately places it on the dedicated detection platform.

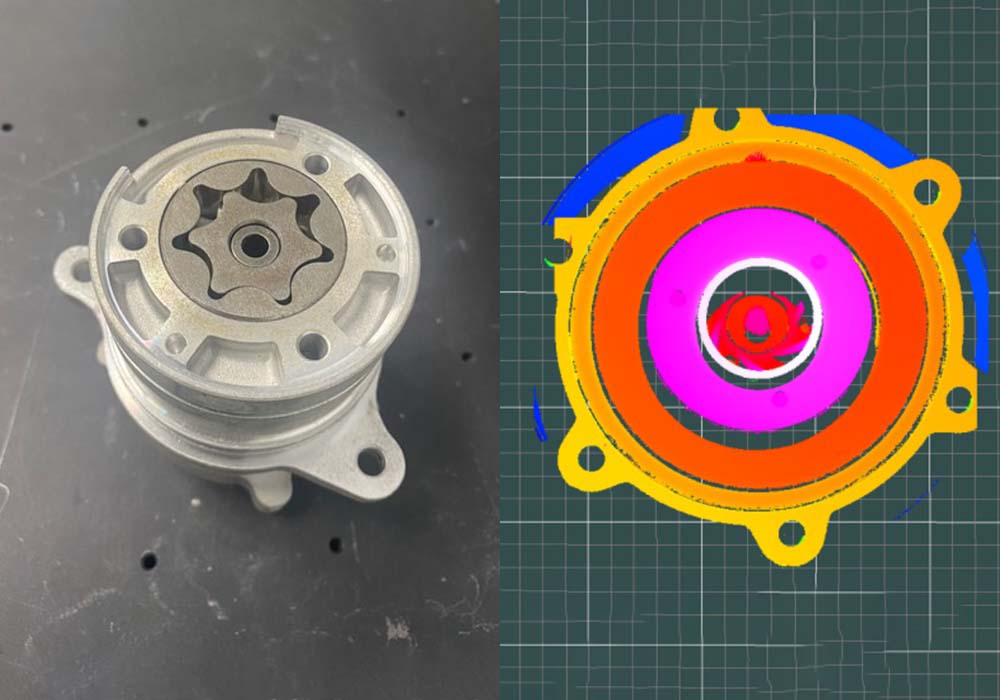

Multi-angle 3D scanning: The detection area is equipped with 6 high-resolution 3D scanning cameras (Keyence VR-5000). These cameras use blue light structured light technology to quickly obtain high-precision 3D data on all surfaces of the water cooling plate.

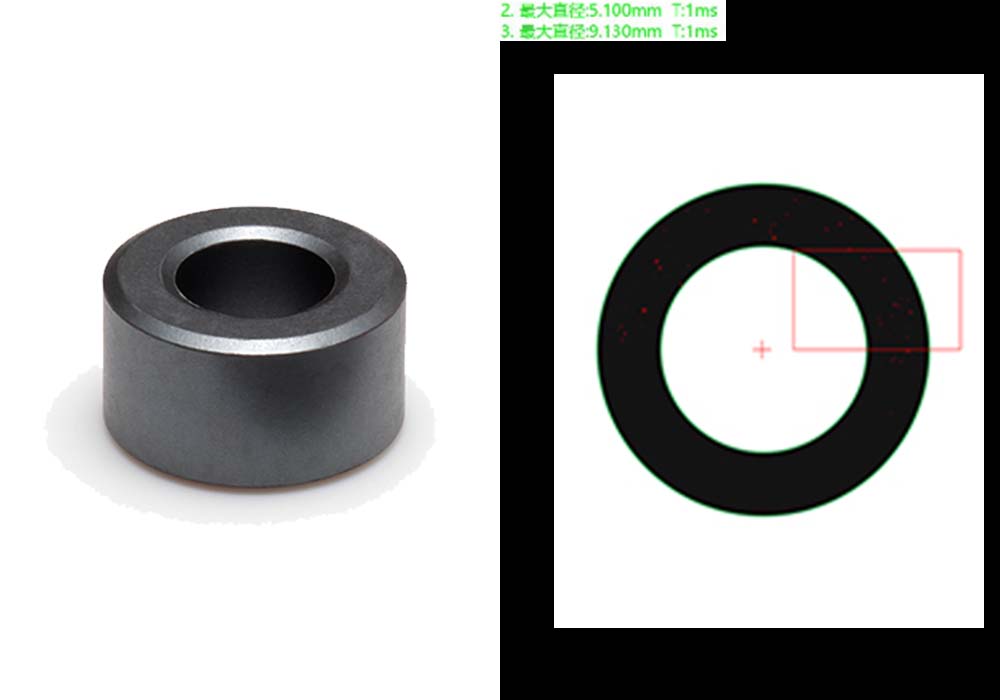

Image processing and analysis: GPU-accelerated computing architecture, combined with specially developed algorithms, can automatically identify the edges of each line on the water cooling plate and measure its contour deviation and position deviation in the three directions of X/Y/Z.

Qualified judgment: The measurement results are compared with the preset tolerance range. If any indicator exceeds the standard, the system will automatically isolate the water-cooled plate assembly.

Data recording: 3D scanning data and measurement results from the entire inspection process will be stored in real time in the central database (Dell PowerEdge R740) to support production optimization and quality traceability.

Real-time monitoring: The inspection data will be displayed in real time on the touch screen of the central control system (Siemens SIMATIC HMI TP1500), and the operator can view the specific measurement data of each water-cooled plate assembly at any time.

Difficulties and solutions:

High-precision 3D scanning:

Difficulty: The surface gloss of the water-cooled plate assembly is high, which is prone to reflection interference and affects the accuracy of 3D scanning.

Solution: The use of blue light structured light technology, combined with a special LED lighting solution (Lumina LM-20 specification), can effectively eliminate reflection interference and obtain high-quality 3D point cloud data.

Fast image processing:

Difficulty: A single water-cooled plate assembly contains a large number of detailed lines, which places high demands on the real-time and accuracy of the image processing algorithm.

Solution: GPU-accelerated parallel computing architecture (NVIDIA Quadro RTX 5000 graphics card), combined with specially optimized algorithms, achieves millisecond-level line profile and position measurement.

Automated loading:

Difficulty: The water-cooling plate assembly has a complex shape and requires precise robot positioning.

Solution: The industrial robot arm (FANUC M-20iA) controlled by visual servo, combined with a special fixture, can quickly and accurately place the water-cooling plate assembly on the inspection platform.