The inspection requirements of the medical industry are very strict. Taking medicine inspection as an example, whether the appearance of the medicine is defective, whether the container for the medicine is qualified, and whether the information on the container is accurate, all need to be ensured to be correct. This involves the screening, classification, storage and distribution of medicines, and ultimately affects the health and life safety of people who use medicines.

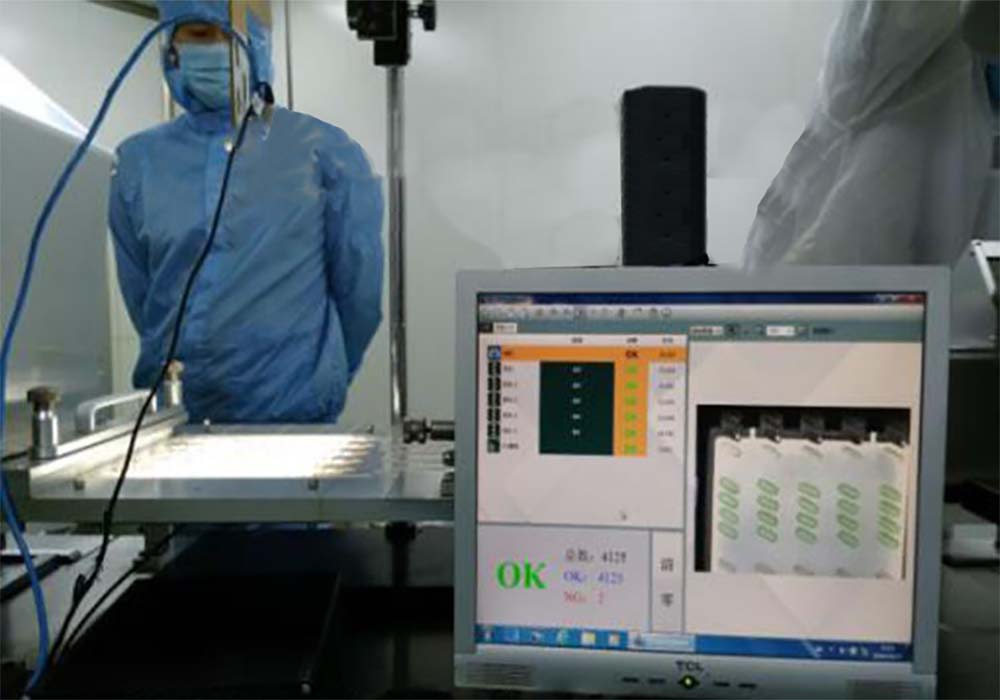

After the liquid medicine is filled, the product name, batch number, and expiration date on the label must be checked to ensure that the batch number and expiration date are clearly printed before the next step of box packaging can be carried out. The machine vision inspection system replaces manual inspection to check whether the printed batch number, expiration date and label are missing, thereby improving production efficiency and reducing the defect rate, avoiding losses to the pharmaceutical company due to defective medicine flowing into the market. The inspection station is between the labeling station and the box packing station.

The following is the label information machine vision inspection machine designed by Intsoft Tech.

Function

Real-time online detection of medicine container label printing defects, missing and incorrectly printed information codes, while detecting whether the labels on the medicine boxes are affixed. If there are any defects in printing or information codes, or labels are missing, the system will alarm in real time, and at the same time, the rejection system will reject defective products, thereby preventing defective products from entering the market and greatly improving the production efficiency of the pharmaceutical production line.

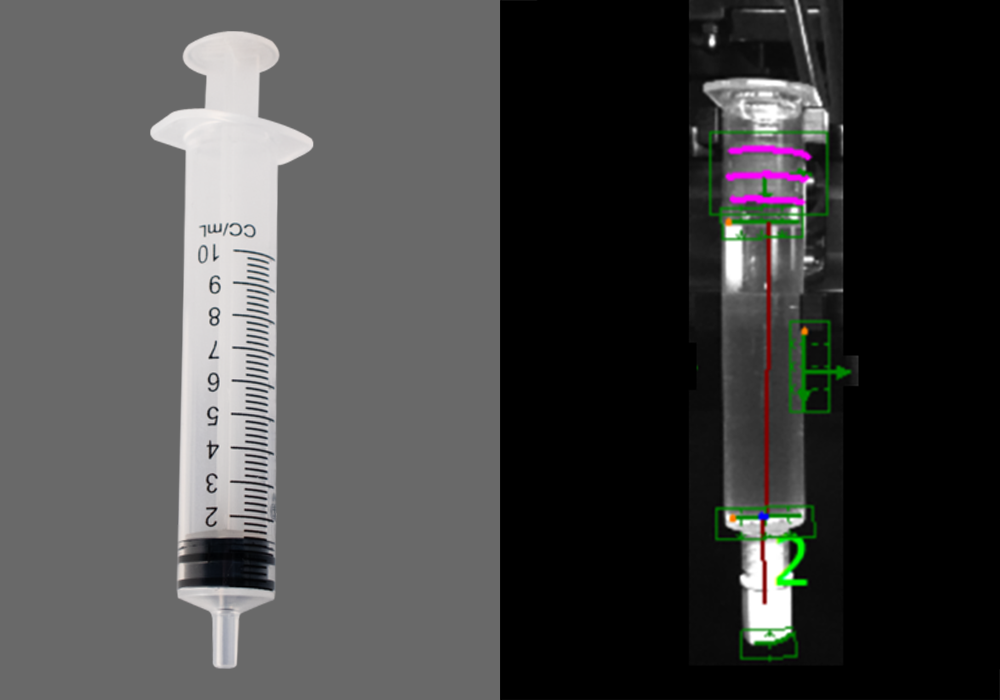

Inspection items

1. Detecting drug labels for misprinted batch codes.

2. Detecting if the batch code of a drug label has been omitted from printing.

3. Detect if drug labels are blurred.

4. Detecting drug labels for missed labelling.

System software composition

1. Image acquisition and OCR module: collect label images and perform optical character recognition.

2. Label information detection module: detects whether the label batch is printed incorrectly or missed.

3. Missing label detection module: detects whether the label is missing.

4. Alarm output template: when the system detects that the label is incorrect, missing and poorly printed, the software alarm outputs and removes the defective label.