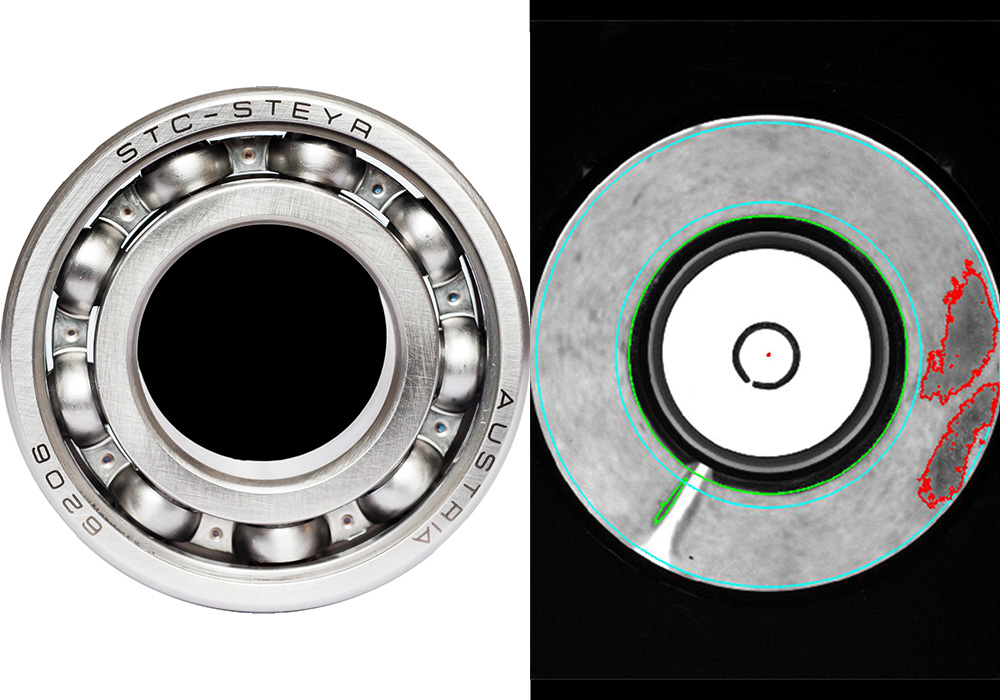

Metal button surface flaw inspection-hardware accessories defect detection

Metal button hardware accessories are used in a variety of scenarios, machinery, clothing, furniture, etc. They are usually used for decorative purposes, so there are strict requirements for the appearance of these buttons. These finished buttons are often accompanied by scratches, dirt, embossing, watermarks, deformation, white plating and other defects,…